Project Description

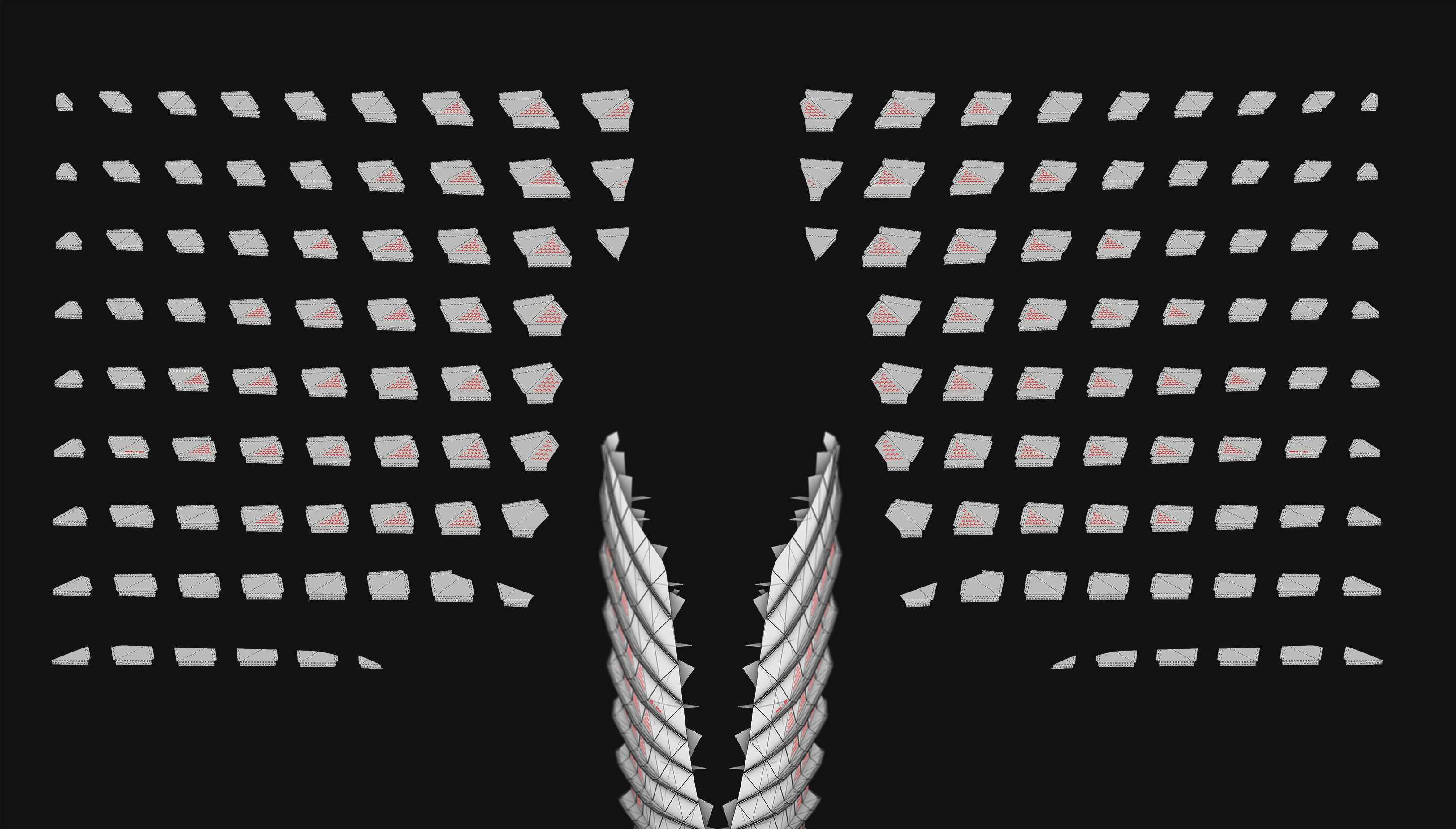

SQUALO is an aluminum cladding system that leverages the power of algorithmic design. The paneling system is designed through a computational workflow that starts with a target design surface. A skewed grid is then wrapped to the surface outlining the boundaries of each panel, and trimmed accordingly. The final panels are then generated from this initial grid taking into account assembling and manufacturing tolerances. Due to the algorithmic nature of the process the design surface can be modified at any time allowing for fast design iterations and explorations.

Assembly Phase

Before assembly the panels are sorted by rows and by column positions. Each row is then placed following the horizontal seam directions, from front to back. The design tolerances introduced, ensured a sufficient amount of flexibility during the assembly, compensating for up to 10mm in vertical alignment and 5 mm in horizontal. The manually folded creases were adapted to the underlying support surface thanks to the thinness of the aluminum sheet used.

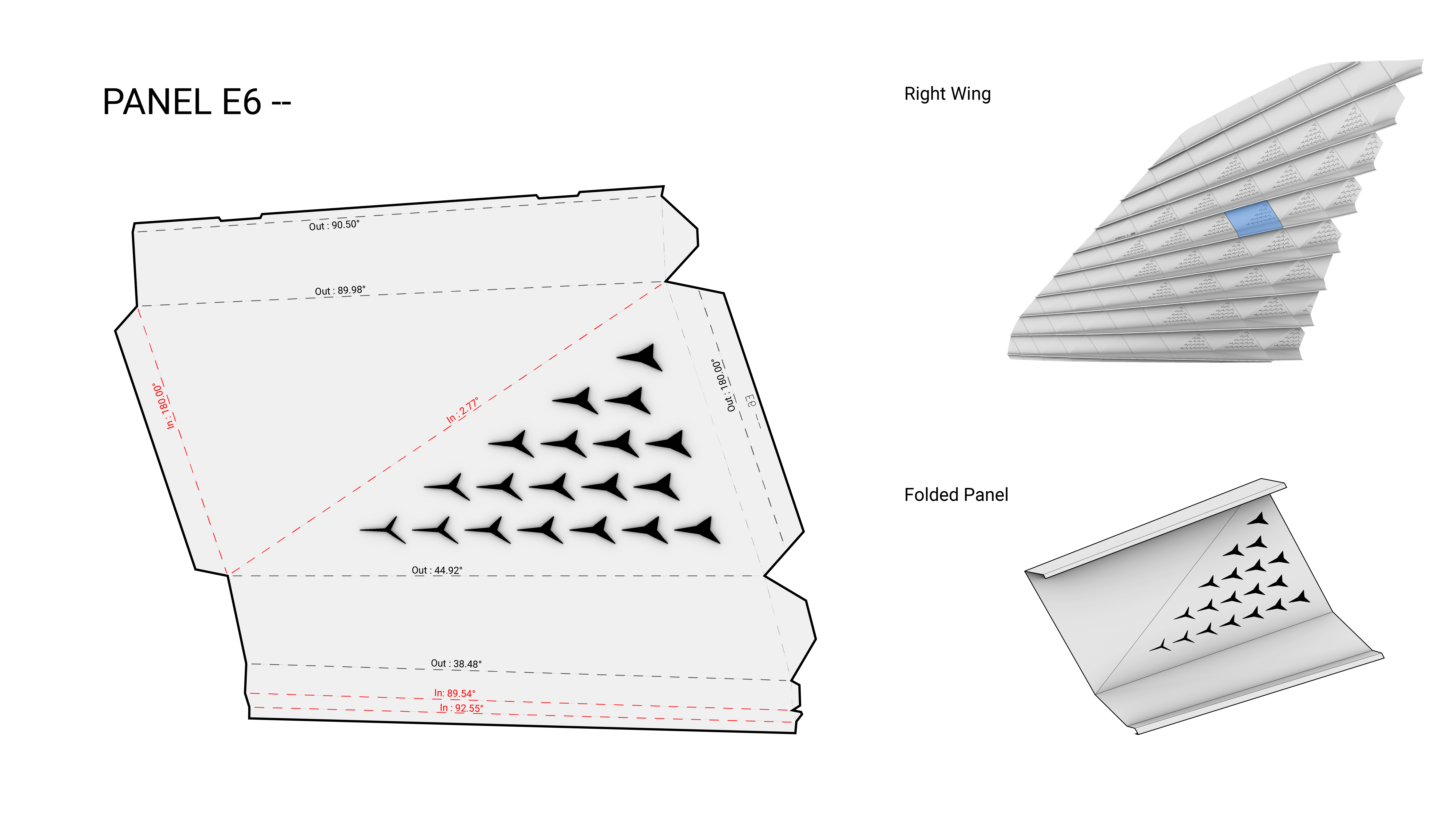

Panel Detailing

For each of the 146 panels that compose SQUALO a detailed view of the panel was drafted both on digital and physical formats. All the information about the folding angles and directions were highlighted on the fold positions. Folding notches were added on the endpoints of each fold line to help workers align each panel on the folding machine faster.

Unfolding Algorithm

All the geometrical details of the cladding elements were designed directly in 3D space, ensuring that each element adhered to the underling surface curvature. Once unfolded, the vertical flat lock seams were added to the design based on the placement tolerances necessary. Similarly unique labels were assigned to each element identifying row and column position on the grid.

images courtesy of INDEXLAB

images courtesy of INDEXLAB

images courtesy of INDEXLAB

images courtesy of INDEXLAB