Project Description

A centrally placed air purifier is enveloped by a free form triangulated aluminum skin. The outside surface is characterized by a varying degree of perforation based on the positions of the air intake and exhaust of the machine. Beneath each triangular aluminum panel is a 3D printed ABS frame that functions as the structural backbone of the system. The bond between panel and frame generate a flexible construction unit that can be adapted to any geometrical configuration, regardless of size or complexity. Although each unit resembles the others in shape, each panel is unique and is the product of an end to end algorithmic workflow.

The Base Plate

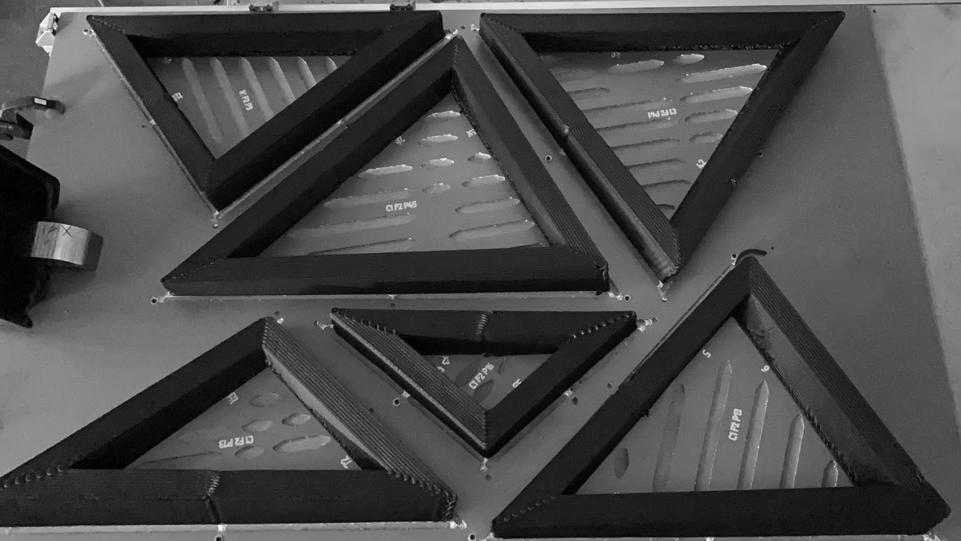

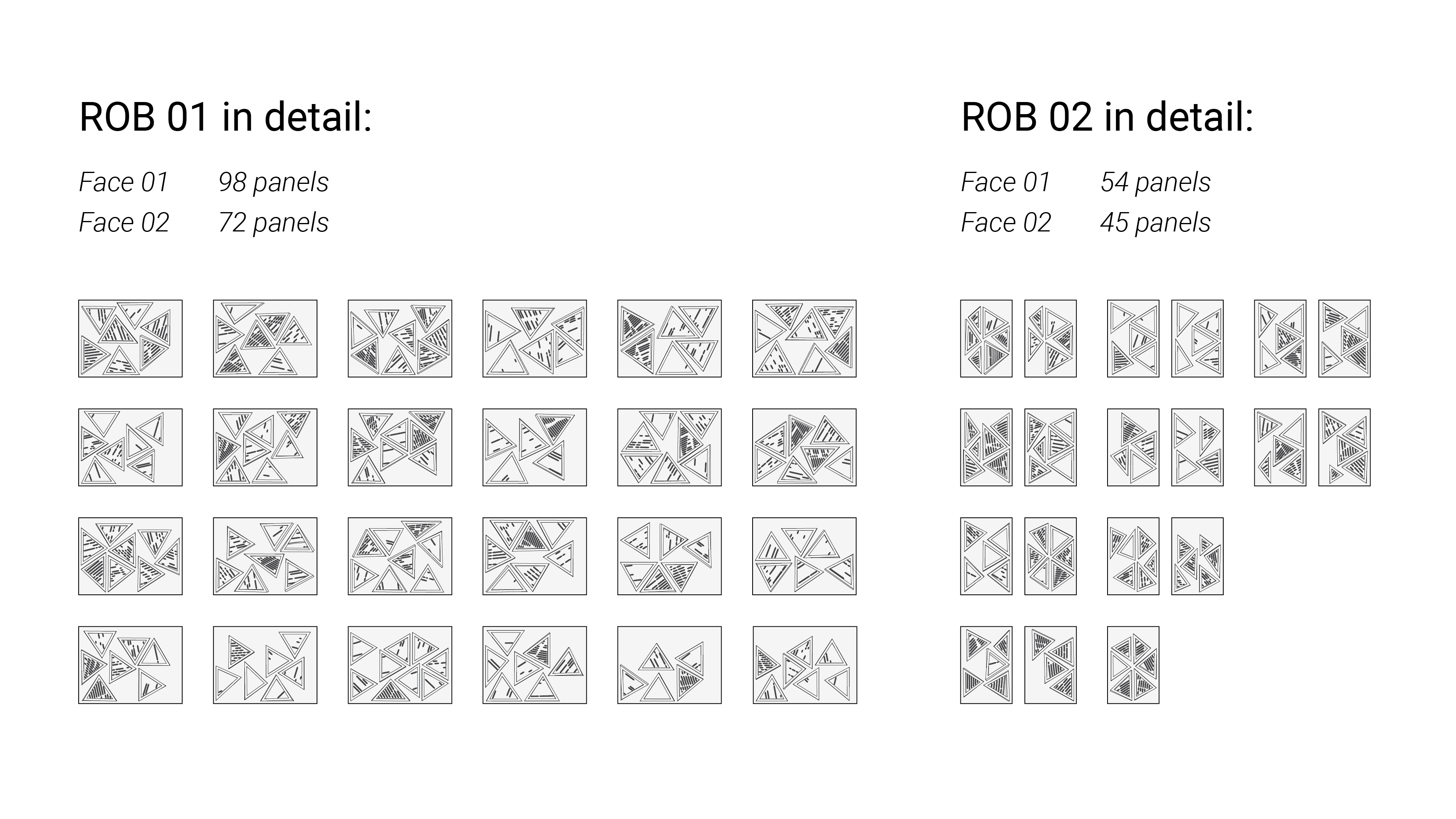

The production files for CAN-ONE were generated directly from the computational workflow and customized for each of the suppliers machines. Every panel is labeled with a unique identifier allowing it to be traced to a precise location in the assembly phases and to a specific production line during the manufacturing stage. Each sheet of aluminum is engineered in order to reduce material waste and optimize the following printing times.

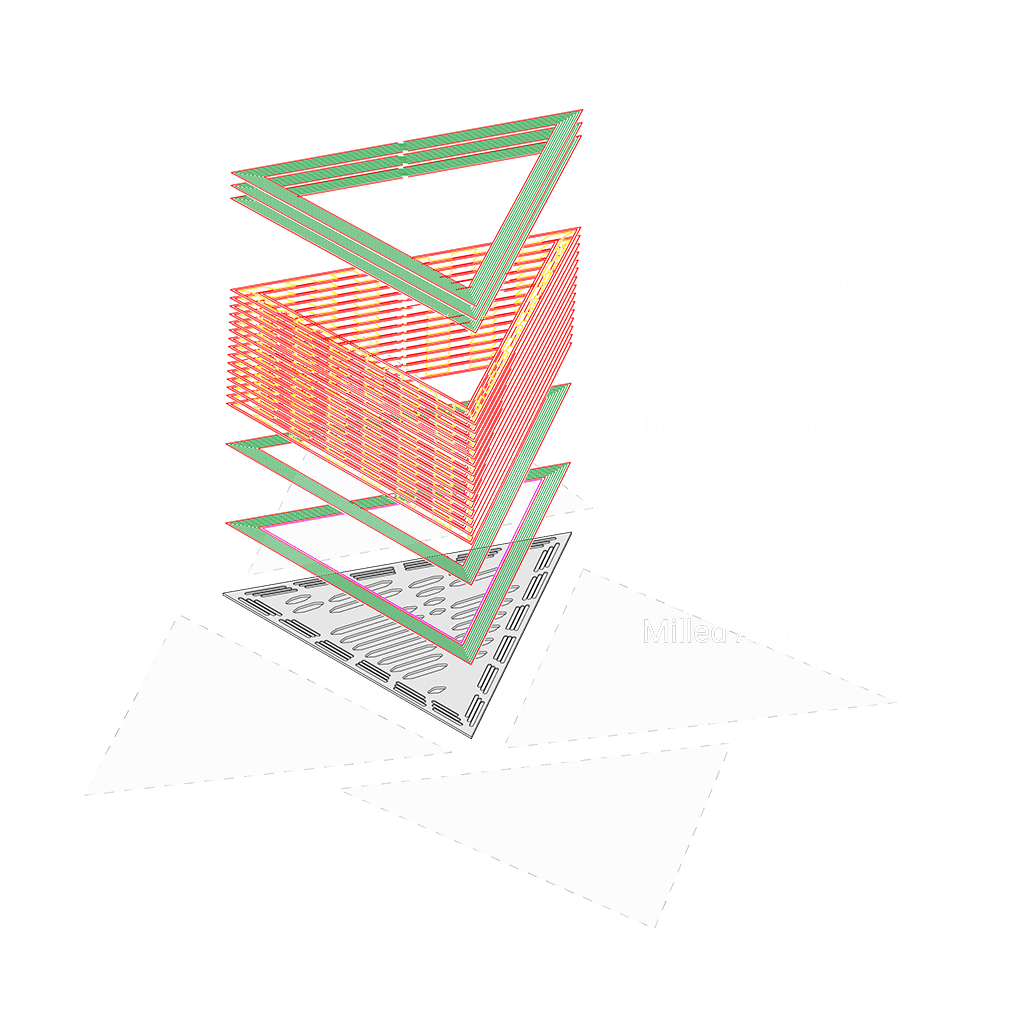

The Unit Module

At the core of the system is a mass-customizable unit composed of the aluminum panel and the 3D printed frame. The printed frame is bonded directly to each panel during the printing phase, resulting in a ready to assemble unit once the printing is complete. All the necessary information for the assembly are contained within the aluminum panel that serves as a template for the module, allowing to streamline the printing process.

The 3D Printed Frame

The 3D printing toolpaths for the frames of CAN-ONE were generated by a custom slicing engine developed specifically for the Robotic Additive Manufacturing cells. Each frame is converted to a series of layers connected through a continuous toolpath in order to minimize travel movements. Each printing parameter, such as speed and extrusion rate, was tuned based on the geometrical features of the 3D frames and the type of extrusion (infill, perimeter, solidfill).

images courtesy of INDEXLAB

images courtesy of INDEXLAB

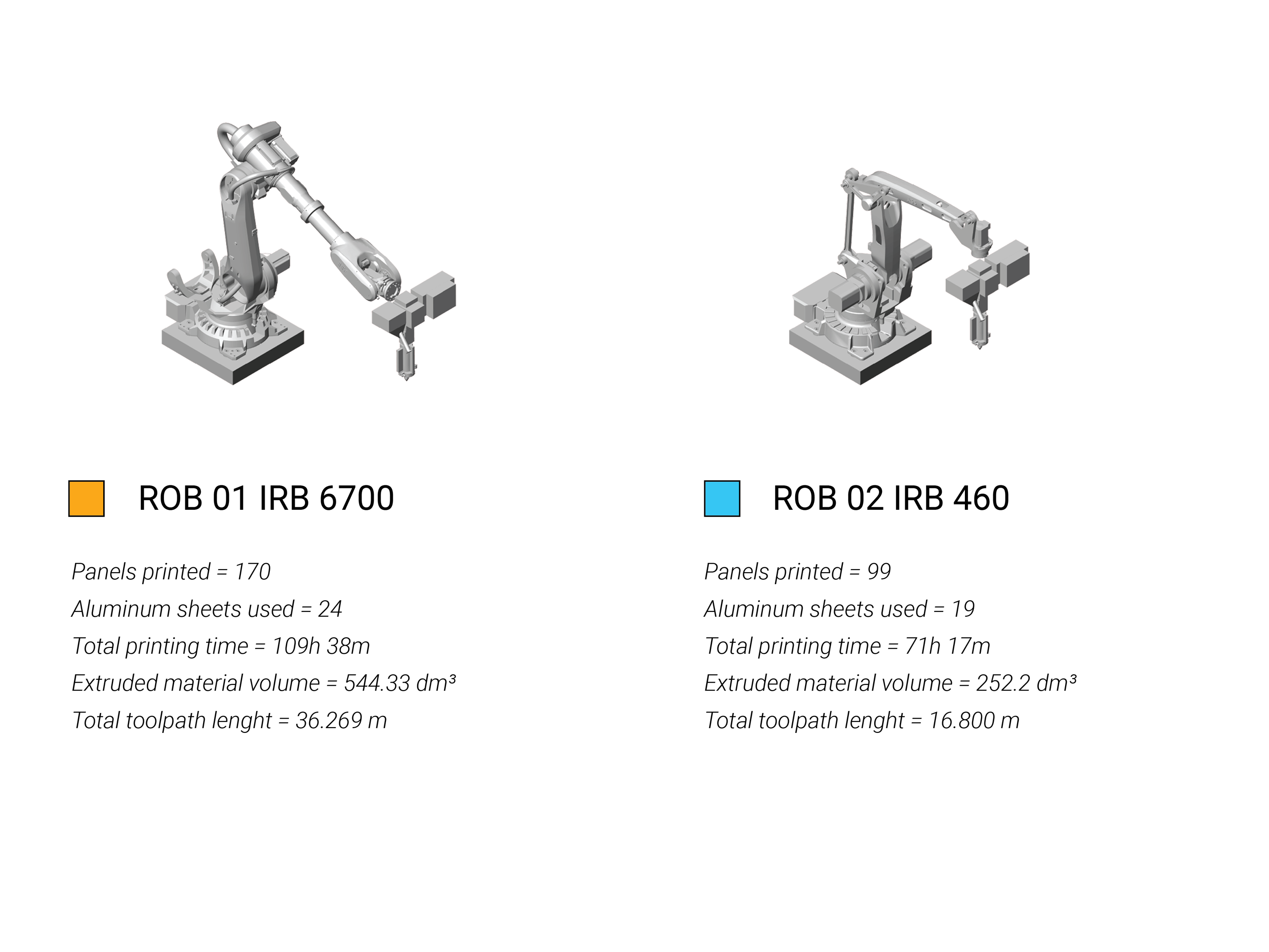

Manufacturing Plan

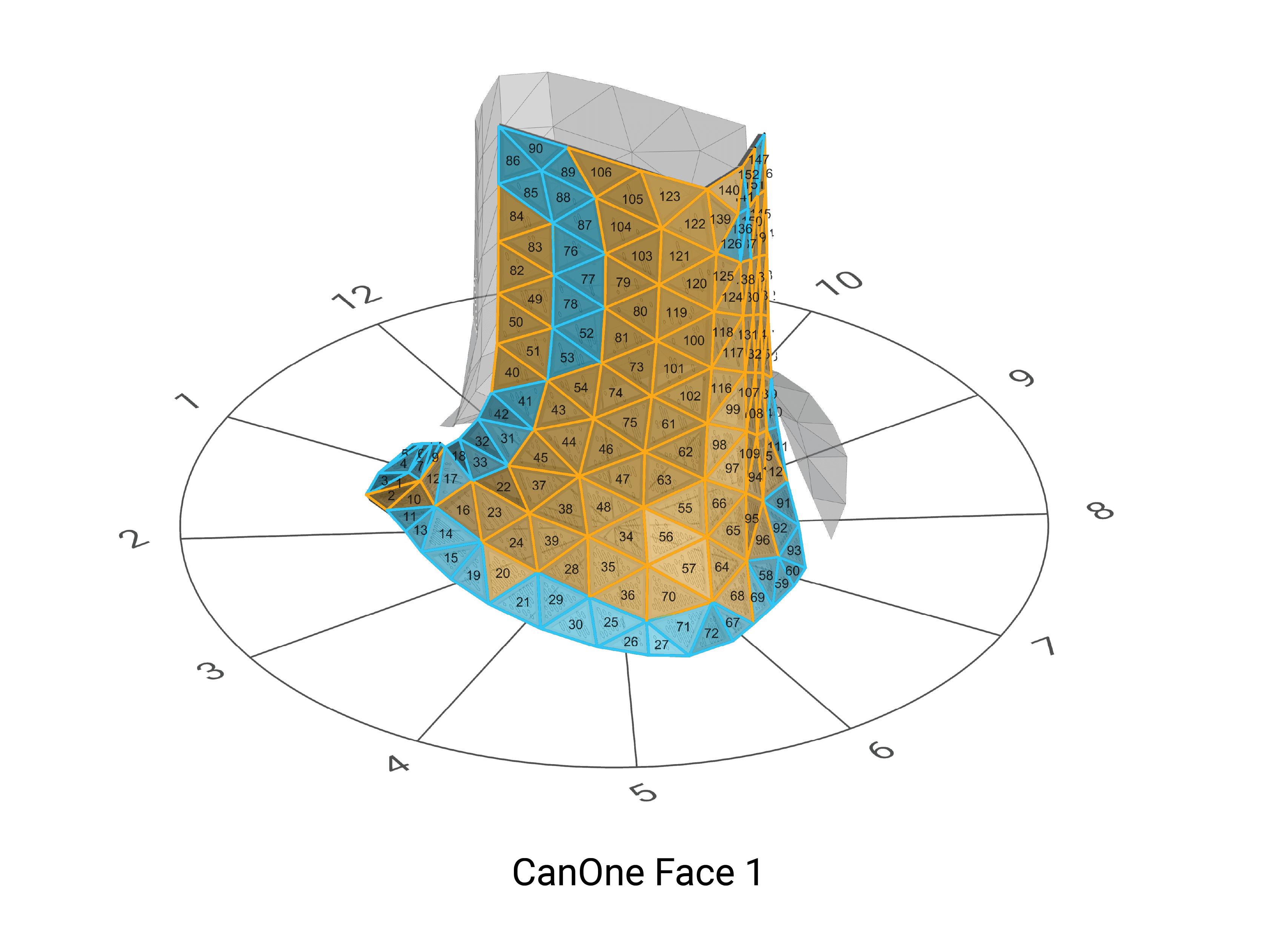

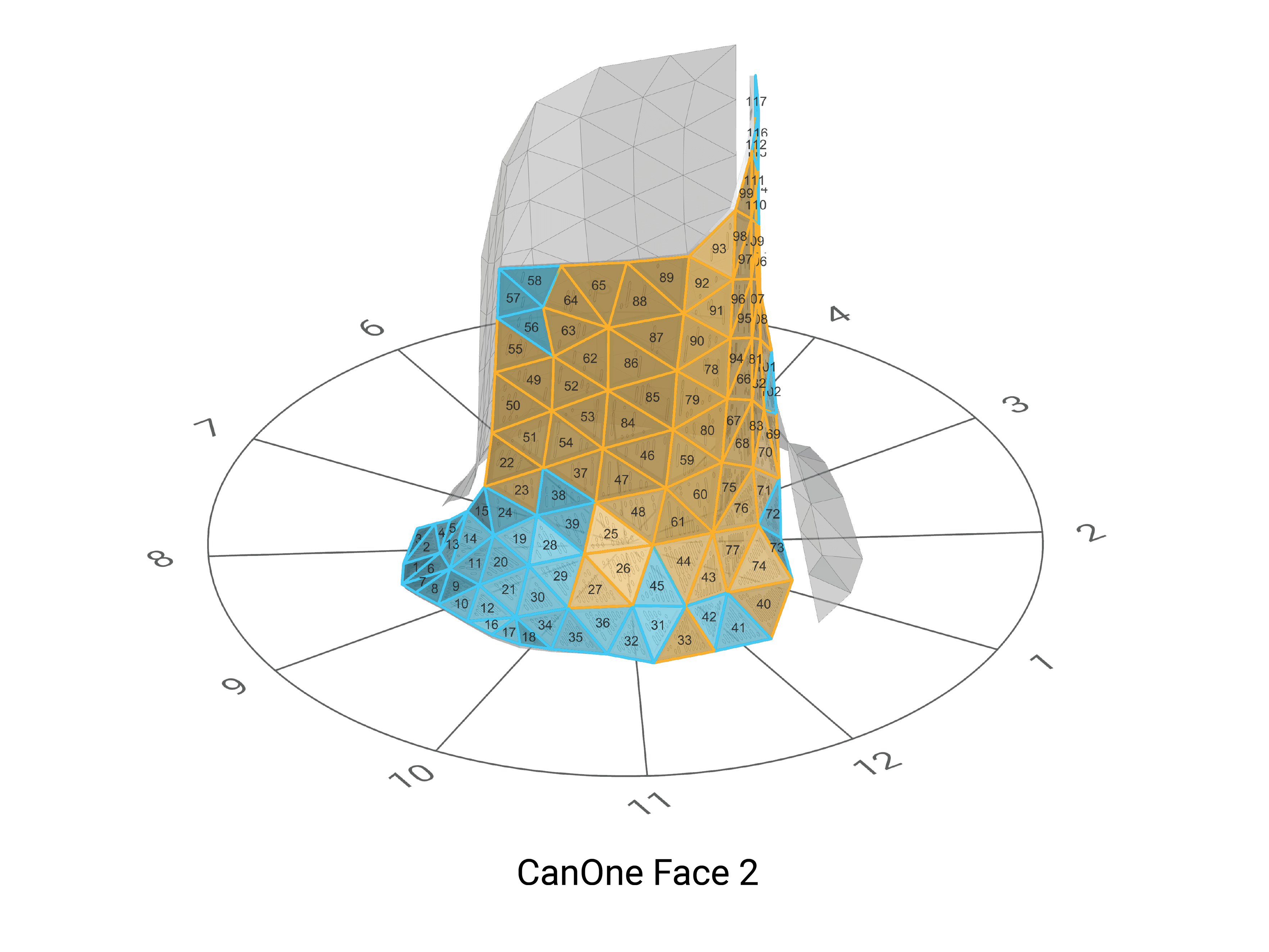

The production of CAN-ONE was split between two robotic 3D printing lines and multiple suppliers for the aluminum milling. Two robotic cells were used, each one with different constraints both in build volume and extrusion capabilities. Each cell worked non stop for 6 days in order to manufacture the 269 frames necessary for the installation. The two faces that compose CAN-ONE were subdivided into two groups in order to achieve a constant average printing time per sheet with a minimum amount of downtime during the harvest of the printed frames.